In the world of metal fabrication, precision and efficiency are paramount. CNC profile cutting machines have emerged as essential tools, offering unparalleled accuracy in cutting complex shapes and profiles in various metals. Whether you’re a large-scale manufacturer or a small business, understanding the benefits and applications of CNC profile cutting machines can help you make informed decisions for your operations.

What is a CNC Profile Cutting Machine?

A CNC profile cutting machine is an advanced cutting tool controlled by computer software. It is designed to cut complex shapes and profiles in materials like steel, aluminum, and other metals with high precision. The machine operates by following pre-programmed instructions (G-code), ensuring consistent and accurate cuts every time.

Types of CNC Profile Cutting Machines

There are several types of CNC profile cutting machines, each suited for specific applications:

- CNC Plasma Profile Cutting Machines:

Ideal for cutting conductive metals like steel and aluminum. These machines use a plasma torch to achieve high-speed cuts with excellent precision. - CNC Flame Profile Cutting Machines:

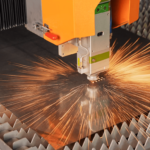

Used for cutting thicker materials, such as carbon steel using oxy-fuel and hydrogen gas for cutting. Flame cutting is highly effective for industrial applications requiring deep, precise cuts. - CNC Laser Profile Cutting Machines:

Known for their precision, laser cutting machines are perfect for intricate designs and thin materials.

Why Choose a CNC Profile Cutting Machine for Metal?

Investing in a CNC profile cutting machine for metal offers several advantages:

- Precision: These machines can cut complex profiles with tight tolerances, ensuring each piece meets exact specifications.

- Efficiency: CNC machines automate the cutting process, significantly reducing production times and increasing throughput.

- Versatility: Suitable for cutting a wide range of metals, from thin sheets to thick plates.

- Cost-Effectiveness: While the initial investment may be high, CNC profile cutting machines reduce material wastage with advanced nesting software and labor costs, leading to long-term savings.

Key Features of CNC Profile Cutting Machines

- Automated Profile Cutting Systems: These systems allow for seamless operation, reducing the need for manual intervention and minimizing the risk of errors.

- CNC Metal Cutting Solutions: CNC profile cutting machines offer comprehensive solutions for cutting metals, providing flexibility and precision across different projects.

- Industrial CNC Profile Cutting: Designed for industrial-scale operations, these machines can handle large volumes of work, making them ideal for manufacturers in industries such as automotive, aerospace, and construction.

Understanding the CNC Profile Cutting Machine Price

The price of a CNC profile cutting machine can vary based on several factors, including the type of machine, cutting technology (plasma, flame, or laser), and the level of automation. While entry-level machines are more affordable, high-end models with advanced features command a higher price. However, the investment in a quality machine often pays off through improved efficiency and reduced operational costs.

The Future of CNC Cutting Technology

With advancements in CNC cutting technology, machines are becoming more precise, faster, and easier to operate. The integration of AI and IoT in automated profile cutting systems is revolutionizing how industries approach metal cutting, offering real-time monitoring and adjustments to optimize performance.

Conclusion

CNC profile cutting machines are transforming the metal fabrication industry by offering precision, efficiency, and versatility. Whether you’re cutting steel, aluminum, or other metals, investing in a CNC profile cutting machine can significantly enhance your production capabilities.

Looking for a reliable CNC profile cutting machine?

Explore ProArc’s range of high-performance machines and find the perfect solution for your metal cutting needs.