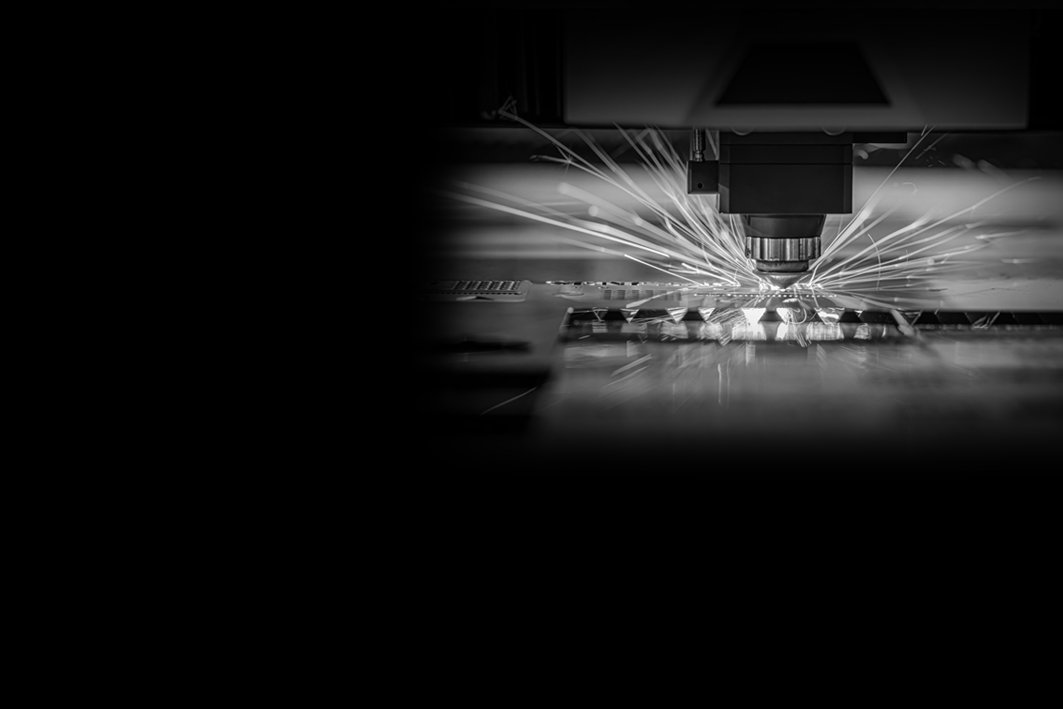

The evolution of CNC technology has revolutionized the world of metal processing. With growing demand for precision, consistency, and faster turnaround, manufacturers are turning to automated CNC industrial machinery to stay competitive. In this article, we explore how this shift is changing the face of industrial manufacturing—and how ProArc is empowering businesses with next-gen solutions.

1. Rise of CNC in Industrial Machinery

CNC (Computer Numerical Control) technology allows machinery to be controlled with precision using programmed commands. When integrated into industrial machinery, CNC enables:

- Repeatable accuracy

- Higher throughput

- Reduced dependency on skilled labor

- Real-time machine monitoring

ProArc’s industrial CNC systems support a wide range of applications—from cutting and welding to marking and profiling—ensuring consistency in every operation.

2. Benefits of CNC Automation

a. Precision & Accuracy

Automated CNC machines perform tasks with micron-level precision, ideal for industries like aerospace, automotive, and heavy engineering.

b. Operational Efficiency

Integrated CNC automation systems speed up the production process by reducing manual intervention and enabling 24/7 operations.

c. Reduced Waste

With fewer human errors and more controlled processes, raw material wastage is minimized—an important factor in cost-sensitive projects.

d. Smart Factory Integration

Today’s CNC robotic automation systems integrate easily with other smart factory technologies, improving data flow, diagnostics, and preventive maintenance.

3. Applications in Metal Processing

Automated CNC manufacturing automation is widely used for:

- Plasma and laser cutting

- Profile cutting

- Pipe cutting

- Precision marking and engraving

ProArc’s automated CNC cutting solutions are trusted across sectors like shipbuilding, construction equipment, and energy fabrication.

4. Why ProArc?

ProArc has been a pioneer in industrial CNC systems for over two decades. Their solutions are known for:

- Customizability

- Precision engineering

- Seamless integration with production lines

- Reliable technical support

Whether you’re setting up a new facility or upgrading legacy machines, ProArc offers tailored solutions for automated CNC machine processes.

Conclusion

As the industry shifts toward smarter, faster, and more precise manufacturing, automated CNC industrial machinery is becoming the backbone of modern metal processing. By adopting intelligent CNC systems from trusted providers like ProArc, manufacturers can boost productivity while maintaining top-tier quality.

Contact ProArc to learn how our advanced CNC solutions can power your production