In the realm of modern manufacturing, the laser cutting machine stands out as a game-changing technology. From small workshops to large industrial operations, these machines offer unparalleled precision and efficiency. In this blog, we’ll explore the different types of laser cutting machines, their applications, and why they are essential in today’s manufacturing processes.

What is a Laser Cutting Machine?

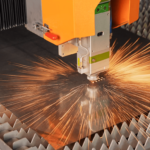

A laser cutting machine uses a focused laser beam to cut through various materials, including metals, plastics, and fabrics. The precision of the laser allows for intricate cuts that are impossible with traditional cutting methods. The machine is controlled by a computer (CNC) which ensures accuracy and repeatability in the cutting process.

Types of Laser Cutting Machines

There are several types of laser cutting machines, each suited to specific applications:

- Fiber Laser Cutting Machine: Known for its efficiency and speed, a fiber laser cutting machine is ideal for cutting metals such as steel, aluminum, and brass. It is widely used in industrial settings due to its ability to handle high volumes of work.

- CO2 Laser Cutting Machine: This type is versatile and can cut a wide range of materials including wood, acrylic, and glass. CO2 laser cutting machines are commonly used in industries such as signage, automotive, and textiles.

- CNC Laser Cutting Machine: Integrating these laser cutting technologies with CNC (Computer Numerical Control), these machines offer precision and flexibility. CNC laser cutting machines are perfect for complex and detailed cuts in metal and other materials.

Applications of Laser Cutting Machines

The versatility of laser cutting machines makes them suitable for a wide range of applications:

- Laser Cutting Machine for Metal: These machines are used in industries such as automotive, aerospace, and construction, where precision and durability are crucial.

- Small Laser Cutting Machines: Ideal for small businesses and workshops, these machines are used for creating custom designs, prototypes, and small-scale production runs.

- High Precision Laser Cutting Machines: Essential for industries that require intricate and accurate cuts, such as electronics and medical device manufacturing.

- Automated Laser Cutting Systems: These systems integrate laser cutting with automation, increasing efficiency and reducing the need for manual intervention.

Benefits of Using a Laser Cutting Machine

Investing in a laser cutting machine offers several advantages:

- Precision: Laser cutting machines can achieve extremely fine and detailed cuts, making them ideal for complex designs.

- Speed: Laser cutting is much faster than traditional cutting methods, increasing productivity and reducing lead times.

- Versatility: These machines can cut a wide variety of materials, from metals to plastics, making them suitable for multiple industries.

- Cost-Effectiveness: While the initial investment might be high, the efficiency and precision of laser cutting machines reduce material waste and labor costs, leading to long-term savings.

Choosing the Right Laser Cutting Machine

When selecting a laser cutting machine, consider the following factors:

- Material: Determine the types of materials you will be cutting. For metals, a fiber laser cutting machine is recommended, while a CO2 laser cutting machine is better suited for non-metals.

- Size and Power: Depending on your production needs, choose a machine that offers the right balance between size, power, and speed.

- Budget: Laser cutting machine prices in India can vary widely, so it’s important to choose a machine that offers the best value for your specific needs.

Laser Cutting Machine Manufacturers in India

India is home to several leading laser cutting machine manufacturers who offer a range of machines tailored to different industries. Whether you’re looking for a small laser cutting machine or an industrial-grade machine, Indian manufacturers provide high-quality options that meet international standards. ProArc is a leading Indian MNC manufacturer of CNC Fiber Laser Cutting machines, serving both the domestic & export market.

Conclusion

The laser cutting machine has revolutionized the manufacturing industry, offering unmatched precision, speed, and versatility. Whether you’re in metal fabrication, automotive manufacturing, or custom design, investing in a laser cutting machine can elevate your business and improve your production processes.

Looking to enhance your manufacturing capabilities?

Explore ProArc’s selection of state-of-the-art laser cutting machines and find the perfect solution for your business!