In the world of metal fabrication, precision, speed, and reliability are paramount. The right metal cutting machine can significantly enhance these factors, enabling manufacturers to meet the demands of various industries. This blog delves into the different types of metal cutting machines, their applications, and how they contribute to the efficiency and precision of modern fabrication.

Understanding Metal Cutting Machines

A metal cutting machine is a versatile tool designed to cut various types of metals with precision. These machines are essential in industries ranging from automotive to aerospace, where the quality of the cut can impact the final product’s performance and durability.

Types of Metal Cutting Machines

There are several types of metal cutting machines, each designed for specific applications:

- CNC Metal Cutting Machine: These machines use computer numerical control (CNC) to automate the cutting process, offering high precision and repeatability. CNC machines are ideal for complex shapes and large production runs.

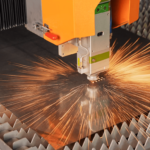

- Laser Metal Cutting Machine: Known for its precision and speed, a laser metal cutting machine uses a focused laser beam to cut through metals. This type of machine is perfect for intricate designs and thin materials.

- Plasma Metal Cutting Machine: Utilizing a plasma torch, this machine is ideal for cutting thicker metals like steel and aluminum. Plasma metal cutting machines are commonly used in heavy-duty industrial applications.

- Metal Sheet Cutting Machine: Designed specifically for cutting metal sheets, these machines are widely used in industries like construction and automotive.

Applications of Metal Cutting Machines

Metal cutting machines are used across various industries for a wide range of applications:

- CNC Steel Cutting Machine: Essential in industries like automotive and construction, CNC machines are used to cut steel with high precision and consistency.

- High Precision Metal Cutting: Industries like aerospace and electronics require extremely precise cuts, which can be achieved with laser or CNC metal cutting machines.

- Heavy-Duty Metal Cutting Machines: Designed for cutting thicker materials, these machines are used in industries such as shipbuilding and heavy equipment manufacturing.

- Industrial Metal Cutting Equipment: Large-scale manufacturing operations rely on industrial-grade metal cutting machines to handle high volumes and maintain production efficiency.

Benefits of Using Metal Cutting Machines

Investing in a metal cutting machine offers numerous advantages:

- Precision: Modern metal cutting machines can achieve extremely accurate cuts, essential for industries that require tight tolerances.

- Efficiency: Automated metal cutting solutions reduce the need for manual intervention, increasing production speed and reducing labor costs.

- Versatility: These machines can handle a wide range of materials and thicknesses, making them suitable for multiple industries.

- Cost-Effectiveness: Despite the initial investment, metal cutting machines can lead to long-term savings by reducing material waste and improving production efficiency.

Automated Metal Cutting Solutions

Automated metal cutting solutions integrate cutting machines with advanced software, allowing for real-time monitoring, adjustments, and optimization. This not only improves precision but also increases production speed and reduces the likelihood of errors. Such solutions are particularly beneficial in large-scale manufacturing environments.

Choosing the Right Metal Cutting Machine

When selecting a metal cutting machine, consider the following factors:

- Material Type: Determine the types of metals you will be cutting, as this will influence the type of machine you need.

- Production Volume: For large-scale operations, an industrial-grade machine with high-speed capabilities is essential.

- Budget: While high-end machines offer more features, it’s important to choose one that aligns with your budget and specific needs.

Conclusion

The right metal cutting machine can transform your fabrication process, enhancing precision, efficiency, and overall production quality. Whether you’re involved in small-scale metalwork or large-scale industrial manufacturing, investing in the right machine is crucial for long-term success.

Looking for a reliable metal cutting machine?

Explore ProArc’s range of high-performance machines and discover the perfect solution for your metal fabrication needs!