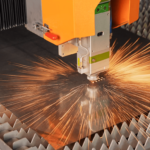

When it comes to cutting metal and other materials with precision and speed, laser cutting machines are the go-to solution. Among the most popular choices are Fiber Laser Cutting Machines and CO2 Laser Cutting Machines. Both types offer unique advantages and are used for various applications in industries like manufacturing, automotive, aerospace, and metal fabrication. In this article, we will compare these two laser cutting technologies to help you decide which one suits your needs.

Understanding Fiber Laser Cutting Machines

Fiber laser cutting machines use a fiber optic cable to amplify the laser beam. These machines are known for their:

- High Precision and Speed: Ideal for cutting thin and thick metal sheets with minimal distortion.

- Energy Efficiency: Lower power consumption compared to CO2 machines.

- Low Maintenance: Requires minimal upkeep and has a long service life.

- Versatility: Suitable for cutting a wide range of metals, including stainless steel, aluminum, brass, and copper.

Understanding CO2 Laser Cutting Machines

CO2 laser cutting machines use a gas mixture to generate the laser beam. They are preferred for:

- Versatile Cutting Capabilities: Suitable for non-metals like wood, acrylic, and plastics.

- Smooth Edge Finishes: Ideal for applications requiring polished edges.

- Lower Initial Investment: Generally less expensive than fiber laser machines.

- Efficiency for Thick Materials: Better suited for cutting thicker, non-metal materials.

Fiber Laser vs. CO2 Laser: Key Differences

| Feature | Fiber Laser Cutting Machines | CO2 Laser Cutting Machines |

| Material Compatibility | Metals only | Metals and non-metals |

| Speed and Precision | High | Moderate |

| Maintenance Requirements | Low | High |

| Energy Consumption | Low | High |

| Initial Investment | High | Moderate |

Which One to Choose?

If you primarily cut metals and require speed and precision, a Fiber Laser Cutting Machine is your best choice. On the other hand, if you work with a variety of materials, including non-metals, and need smooth edges, consider a CO2 Laser Cutting Machine.

Conclusion

Choosing between fiber laser and CO2 laser cutting machines ultimately depends on your specific application, material types, and budget. For metal-intensive tasks, fiber laser cutting machines are the superior option. However, if versatility and lower initial costs are your priority, CO2 laser machines may be the way to go.